Ewarenow Blog

Continuous Improvement as a Way of Life

Six suggestions on making CONTINUOUS IMPROVEMENT a way of life in your organization. Now more than ever doing so is necessary for most companies’ survival and growth. Ewarenow and most of its customers and partners embrace it.

It’s your organization. It’s unique. So clearly you should implement continuous improvement your way. Hopefully, these suggestions may help your own thinking.

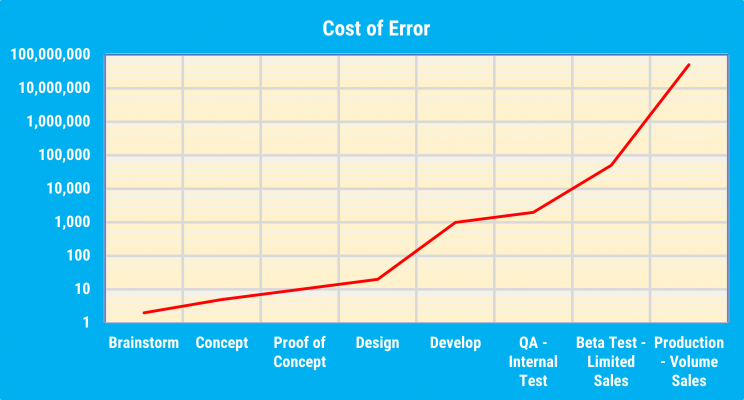

Ensure everyone knows the later in a life-cycle process an error is detected, the higher the cost in money, resources, reputation, and even lives.

The cost rise is exponential. Samsung discovered that with the Galaxy Note 7 smartphone. Omitting or shortcutting valid steps in a development lifecycle can be exceedingly expensive false economy. Investing in more analysis and dispassionate critique of early-stage results has high ROI.

NOTE: The Cost of Error graph at the top of the page is just conceptual, but the message it conveys is valid.

Ensure everyone knows continuous improvement is more than a policy or a program. It is a core part of your company culture. And that may be quite different than the culture some of the workers were raised in.

My very good friend and business partner, Hung H. (Harry) Le is a naturalized American citizen and the CEO of Enclave in Vietnam. He says one of aspect of the company’s business culture is to, “Overcome 3000 years of Vietnamese culture” so the workers think for themselves, make suggestions, and question direction that they think is wrong. And that is not just a Vietnamese thing.

Ensure everyone knows they are invited and encouraged to suggest ideas and to question what they think may be wrong. Not everything they suggest will be carried out, but their effort is appreciated and respected.

You may want to be a bit flexible when a worker’s idea is not quite the same as what you would choose. Is it good and effective, just not ‘my way’? When that happens, I usually compliment the worker and say, ‘Make it so.” My reward is more good ideas from the worker and less thinking required by me at that level of detail. And when the worker’s idea isn’t acceptable, I cordially explain why. They learn something and remain encouraged to propose their ideas.

Ensure everyone knows that quality comes first – always!

You succeed best if you build quality in. As Dave Cutler, the architect of the Microsoft Windows kernel, says, ‘If you don’t put them [bugs] in, you don’t have to take them out.” But you still need solid Quality Assurance processes. See my 2019 LinkedIn article on Boeing’s 737 MAX MCAS as a counter example.

Ewarenow’s development teams produce deliverables every 1-2 weeks. Occasionally, a team leader will contact me on Friday to say, “The QA work is not done. Can we have until Monday?” I have always said, “Yes”. If the customer is expecting the deliverable on Friday, we notify them of the delay to get it done right. They say, “Thanks.”

Ensure everyone knows admitting and learning from mistakes is good but ignoring or concealing them is verboten.

The story goes that the head of a General Electric business unit met with CEO Jack Welch to say that he had made a $17 million mistake. He explained it and admitted what he should have done. He handed Jack his resignation letter. Jack tore it up and said, “You cannot resign. I just invested $17 million in your education. Get back to work.”

A user of a web app we developed reported a problem in the Instrument Interface module. We determined that the code in the new web app mirrored code in the legacy app it replaced. My guidance to the development team was, “Don’t model it on the old code. That part of the module was an afterthought and the QA was shoddy. My bad!”

Ensure everyone knows preventing mistakes is one of the best kinds of improvement.

Decades ago W. Edwards Deming said, “When something goes wrong, chances are 85% that it is the fault of the system, and 15% that the individual worker is at fault.” The characteristics of ‘the system’ are far different now, but Dr. Deming’s overall point is still valid.

Erin, the QA Officer at a water testing laboratory discovered over 500 cases of the person logging a new water sample into the business app not entering a legitimate date/time the water sample was collected. Diagnosis: The app defaults it to ‘Now’ unless the user specifically overrides it. The system is at fault. Cure: change the system to require the user to enter it and then verify that its earlier than ‘Now’.

Thanks for taking the time to read this. If you got here from LinkedIn, I’ll be grateful for your assessment in LinkedIn (Like, Comment, Share). Or you can respond via email on the Ewarenow Get In Touch page.